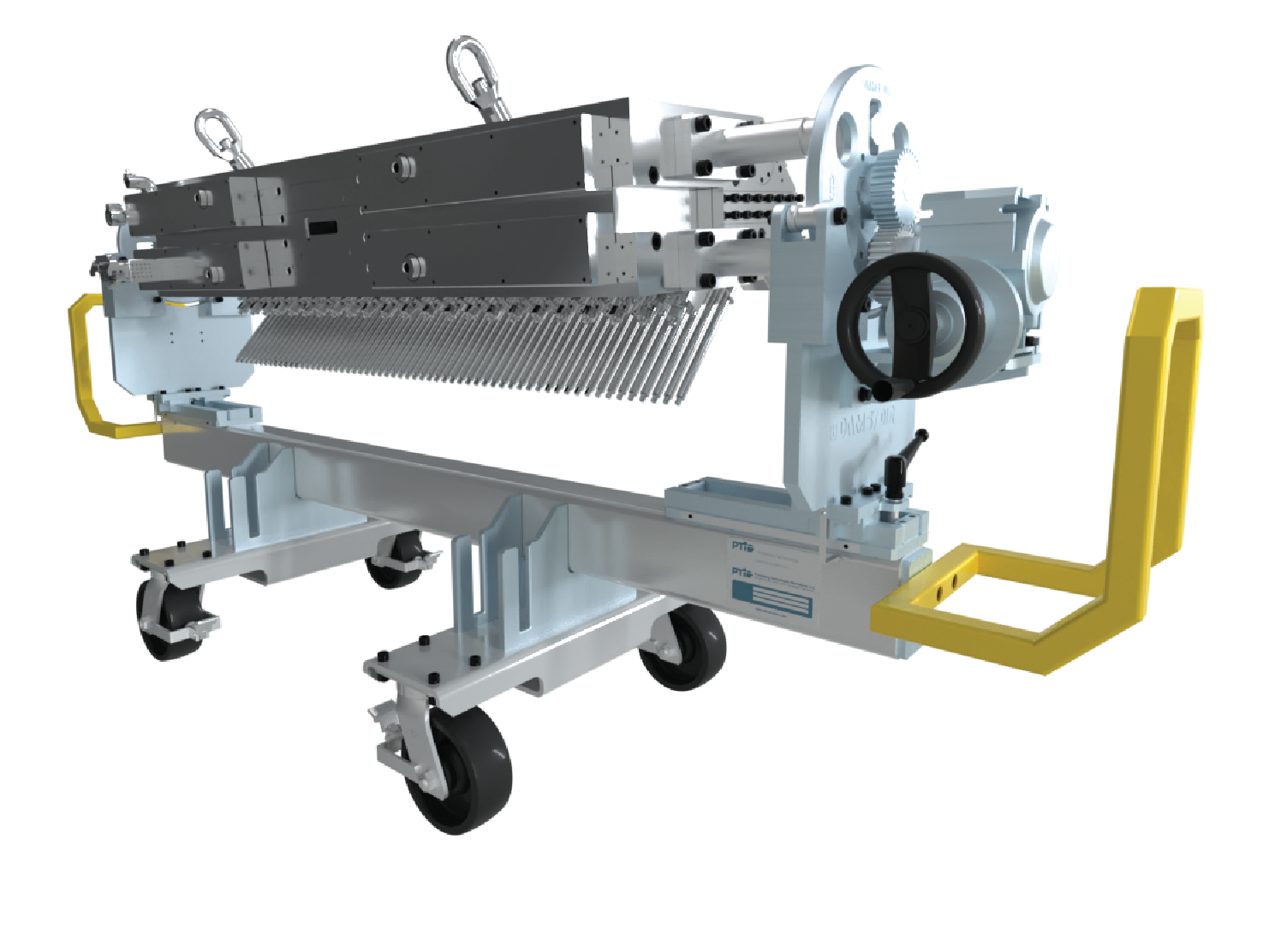

uCAMS™/DR

(universal Cleaning Assembly Maintenance System Die Rotator)

Designed specifically for handling flat dies (cast or sheet), uCAMS™/DR serves as an essential ‘tool’ for managing the

difficult task of removing and transporting dies from the extrusion line.

The uCAMS™/DR simplifies die removal and reinstallation, offering greater protection to personnel

and company assets!

Due to various spatial constraints an extrusion die can often be the most difficult to access, especially for purposes of

inspection and servicing. Standard procedures require roll stand retraction with the workspace surrounding the die and roll

stand often constricted with little to no cross-machine direction space available. The compact footprint associated with

uCAMS™/DR allows for easy maneuverability between the sheet die mounting location and the retracted roll stand.

uCAMS™/DR simplifies the job of either removing or remounting a die from the extrusion line minimizing risks to people and

equipment. Using uCAMS™/DR to transport the die to the position (immediately adjacent to the re-installation location) and

rotating it to the angle desired greatly simplifies the process of re-mounting a die. Using uCAMS™/DR simply involves a

straight lift between the uCAMS™/DR rotation cradles and the remounting position on the extrusion line, thereby eliminating

multiple alignment attempts and temporary sawhorses or wood skids commonly used today. Furthermore, the challenges of

handling a die that weighs several thousand pounds are minimized to a single operator now capable of rotating the die to the

proper orientation.

uCAMS™/DR Advantages

The uCAMS™/DR provides significant advantages over current die removal and inspection procedures. The unique design of the uCAMS™/DR…

- Allows compact cart to fit directly beneath die mount position for ease of die removal and transport

- Permits safe 360 degree rotation for orienting dies to/from horizontal, vertical or angled positions (complex configurations common to vertical, horizontal or j-stack roll stands)

- Provides the means for die rotation to occur thru the axis center-of-gravity for stable and safe operation

- Eliminates risky die rigging/manipulations onto pallets, plywood or carboard surfaces

- Serves as an inspection and maintenance workstation, positioned at a safe ergonomic height for operator

- Offers compatibility with a variety of die sizes due to its adjustable width settings situated on linear bearing glides

- Transports dies safely to/from uCAMS™ service location for additional maintenance processes of splitting/cleaning/servicing functions

Ergonomic grab bars for moving the cart with large casters with wheel locks allow for ease of moving an positioning

Easy glide linear bearings for precise travers with hold-open lock to secure positioning

Rack and Pinion design, along with a large hand wheel, allows single person die splitting with ease

Cradle design permits safe positioning and smooth rotation of the die bodies

Large onboard toolbox securely stores necessary supplies and tools

Onboard caddies keep die trunnions organized and readily accessible

Click on the icon below for uCAMS plus

Click below for more information about uCAMS DR