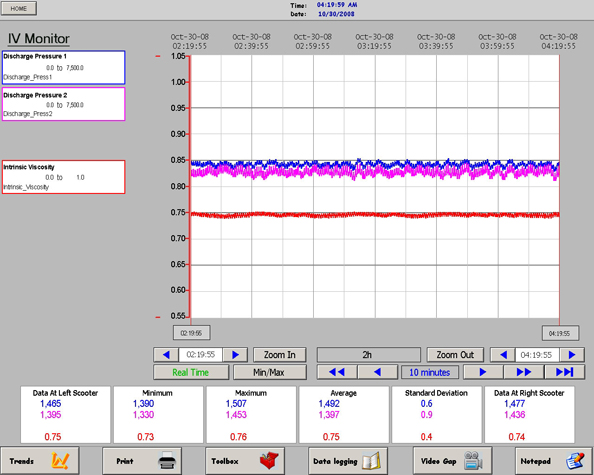

Real Time IV Monitoring

In PET extrusion, the maintenance and preservation of the material IV is a key requirement of the process. Intrinsic Viscosity (IV) is a measure of the molecular weight of PET. The mechanical characteristics of PET are improved at higher molecular weight (higher IV) and worse at lower molecular weight (lower IV). Should the IV of the extruded PET sheet drop below acceptable thresholds, the end product mechanical properties of the sheet will be compromised to unacceptable levels. The ability to monitor and track the relative level of the material IV in-process and in real-time is an invaluable process tool. Identifying any deviation in the processing conditions and being able to take corrective action to address those conditions is key to maintaining consistent and efficient production. The display and recording of this information is typically fed into PTi's flagship TITAN® control system, where it can be displayed, stored and readily accessed. The unique technology represented in PTi's real-time IV Monitoring System is based on a precise measurement of melt temperature and capillary piping pressures such that the viscosity and subsequent IV can be accurately calculated. These results are benchmarked against the ASTM Solution Test Method for measuring IV and possesses an accuracy of +/- 0.02 dl/g.