Featured News - Current News - Archived News - News Categories

PTi Announces Its Newest Dryerless Twin Screw Extruder Series SGTSE MultiRESN™—MADE IN THE USA

by Samantha Sliwa

March 25, 2025— Processing Technologies International, LLC (PTi), Aurora, IL PTi has announced that it is evolving the HVTSE® brand name to align with the current lineup of extruders, with emphasis placed on its significance as a SUPER-G® Twin Screw Extruder with Multi-Resin capabilities, referred to as SGTSE MultiRESN™

PTi’s HVTSE® line has undoubtedly led the market in dryerless extrusion technology, with the High Vacuum Twin Screw Extrusion (HVTSE®) systems dominating in the areas of energy efficiency, multi-resin capabilities, and dryerless technology. Stressing its inclusion within the SUPER-G® Series of extruders, correlating technology, and substantial sustainable value achieved through multi-resin processing capabilities, means evolving the name to something identifiable and inclusive of its pertinent attributes.

The SGTSE MultiRESN™ model is not new to the product line, as it has been in production for a little over two years now. Improvements have been implemented over time to meet industry demands and processing capabilities. Originally established and operating as a 90mm 50/LD, 430 hp oil cooled, co-rotating twin screw in PTi’s Technology Development Center (TDC), the SGTSE MultiRESN™ has proven to be unwavering in power and versatility, without compromise to the HVTSE® standards of efficiency. Maintaining the premise of fully intermeshing co-rotating, self-wiping screws, with high vacuum venting for the elimination of the crystallizing and drying processes, the SGTSE MultiRESN™ outperforms other twin-screw technology in terms of operating performance, energy efficiency, and sustainable utilization of resources.

Capable of processing a variety of virgin, post-consumer ,post-industrial resins and flake, including PET, PLA, PP, PS, PE and other unique blends, without first having to crystallize, dry or change screws, the SUPER-G® Twin Screw Extruder with Multi-Resin capabilities offers significant advantages to a processor. Capital equipment needs, floor space, logistics, associated labor and energy usage are minimized or eliminated with dryerless technology. The added capability to process a multitude of resins on one extrusion system leads to greater versatility and opportunities for the processor to meet consumer demands.

The SGTSE MultiRESN™ speaks to processor sustainability goals and standards in terms of energy efficiency and resource management. Energy efficient designs target sensible production rate ranges well suited in today’s production environments, with increased efficiency ratings of over 20%. The newly configured square barrels design heats up faster with higher heater-to-barrel mass density ratios vs that of round barrel counterparts, resulting in heat-up times reduced by as much as 30%. Resins (pellet, flake, and process scrap) can be immediately introduced into the process without drying, further saving energy while utilizing the most available resources. Furthermore, the starve fed system means blends, colors, and quick change overs can be accomplished on the fly and in as little as 20 minutes reducing downtime, maintenance and startup times.

Like the HVTSE®, PTi standards and technology have been integrated into the SGTSE MultiRESN™, including, but not limited to, PTi’s patented M-ATEX™ technology which allows free thermal expansion of the equipment, the TITAN® Control system, and RealTIME™ IV monitoring. This newest machine series features many improvements over past designs, including:

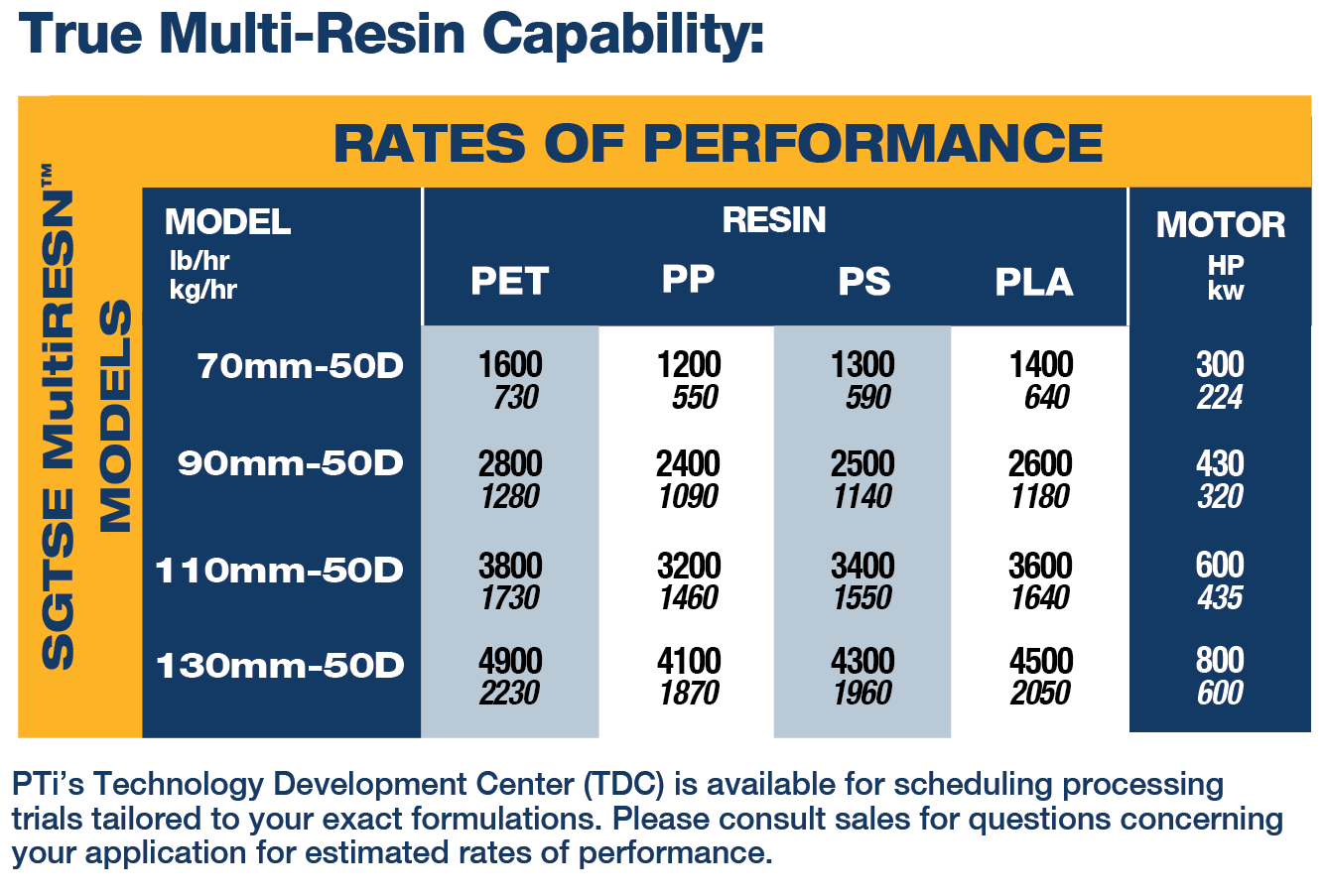

- TARGETED SIZES. Machine sizes coincide with processor needs. Model size capacities align with production targets. (See Performance Chart, Figure 2).

- MODULAR COMPONENTS. Fully welded modular barrel sections with liquid cooled cores (eliminating 350+ hydraulic barrel cooling plugs) are engineered with specific metallurgies for extended component life. (See Figure 3.) Additionally, the square barrel segments (2 unique non-vented and vented) provide an incremental balanced process profile and cost-effective serviceability.

- HEAT RETENTION. Oven-style barrel guards (integrated thermal guards) provide toolless access and excellent heat retention. (See Figure 4.)

- ENERGY EFFICIENT. Cast bronze and aluminum high-watt density heaters use targeted energy theory to maximize efficiency and overall machine performance.

- HIGH TORQUE RATED. Screw elements feature full length inner-splined bores for improved torque ratings.

- UNIQUE SCREW REMOVAL. The drive end de-couples from the downstream barrel section to permit screw removal out-the-back for reduced footprint requirements and ease of service and inspection. (See Figure 5).

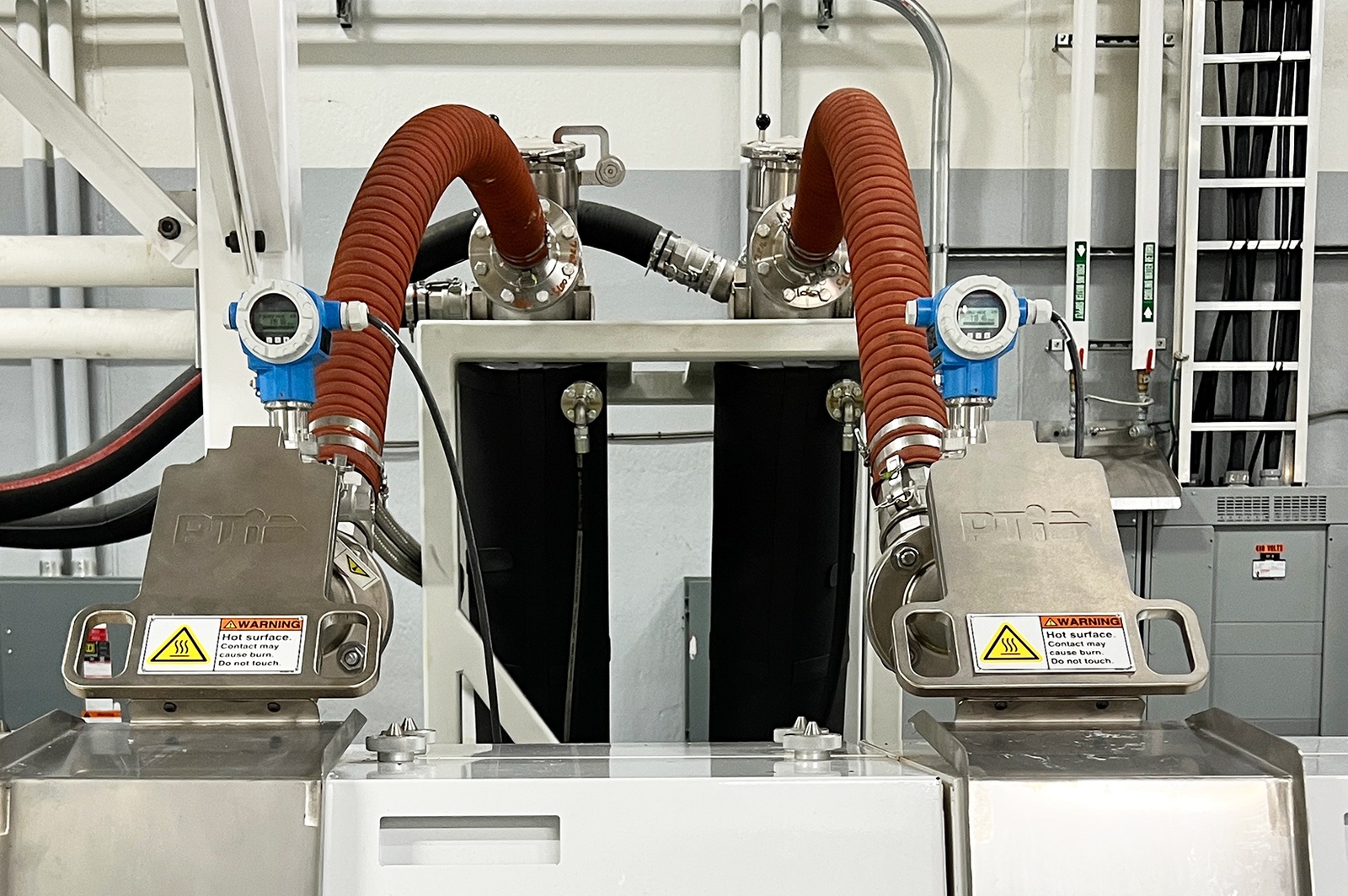

- STAINLESS STEEL. High vacuum circuits offer all stainless-steel construction to assure long component life and superior performance with toolless access clean out hatches (See Figure 6).

- HIGHER OUTPUTS. Overall machine design yields 15+% greater production outputs per horsepower (HP), making it highly efficient.

- MADE IN THE USA. SGTSE MultiRESN™ twin screw extruders are made by PTi in Aurora, Illinois.

Furthermore, the SGTSE MultiRESN™ equipment footprint has migrated from a L/D of 52 to L/D of 50, with equivalent or greater output rates of previous HVTSE® models. See Figure 2 for model and performance rates per application processes.

The SGTSE MultiRESN™ 90mm currently resides in PTi’s TDC as a full production line capable of conducting tailored trials and formulations.

For information regarding SGTSE MultiRESN™ capabilities and or trials, contact PTi at 630.585.5800 or reach out to a sales representative at PTi - World Class Extrusion Systems.

For more information on the SGTSE MultiRESN™ click here https://www.ptiextruders.com/sgtse

Figure 1. Picture above represents a SGTSE MultiRESN™ 90mm with die assembly.

Figure 2. SGTSE MultiRESN™ rates of performance by model and resin type.

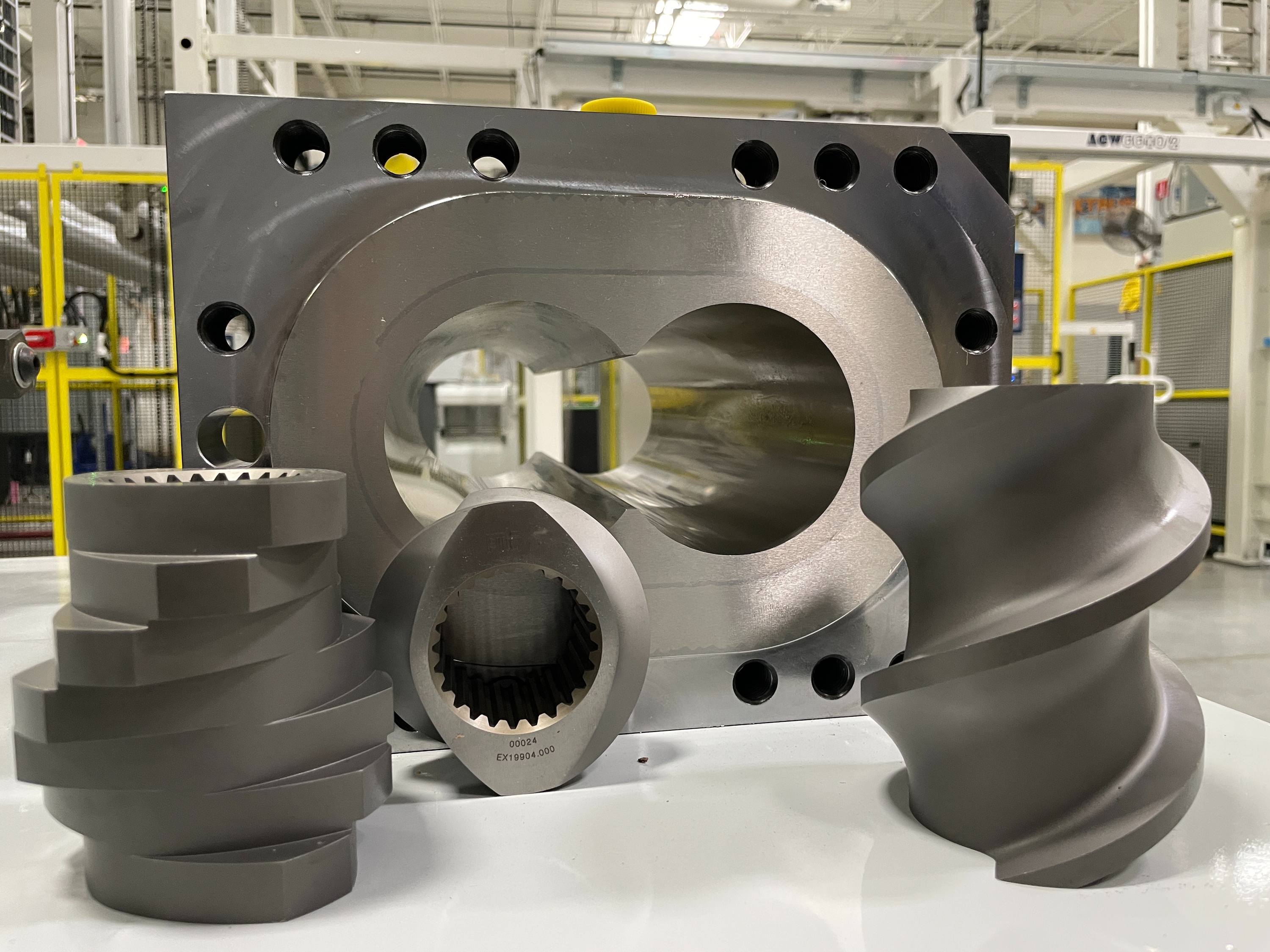

Figure 3. SGTSE MultiRESN™ fully welded modular barrel sections, featuring liquid-cooled cores that eliminate over 350 hydraulic plugs, are coupled with high-torque-rated screw elements with full-length spline bores.

Figure 4. Oven style guards for high heat retention, cast bronze and aluminum heaters use a targeted energy theory to deploy energy where the process demands it.

Figure 5. The SGTSE MultiRESN™ frame bulkhead provides a machine-split feature for ease of screw removal out-the-back side of the extruder.\

Figure 6. The SGTSE MultiRESN™stainless steel vent port assemblies provide ease of venting area access and eliminates corrosive tendencies due to high moisture level removal.

#####

About Processing Technologies International, LLC (PTi)

Processing Technologies International, LLC, based in Aurora, Ill. Established in 1988, PTi is a leading global manufacturer of high-performance sheet extrusion machinery. PTi designs, manufactures and services precision equipment that converts filled and unfilled resins into sheet for a broad range of end-use markets including. packaging, construction, automotive, lawn and garden, office products, signage and displays, and appliances. PTi’s extrusion systems are engineered to exacting standards and offer an exceptional range of design features resulting in superior equipment performance, while producing the highest quality sheet industry wide. More information is available by calling (630) 585-5800 or visit www.ptiextruders.com.

For more information, press only:

Kathleen Flannery

630-585-5800