GENESIS™ Program Featured Line:

PTi's HVTSE® (High Vacuum Twin Screw Extrusion), a dryerless inline extrusion system, is well suited for processors seeking multi-resin product capabilities, energy efficiencies and scrap recovery. The ability to process a variety of resins, such as PET, PP, PS, HDPE, PLA, PETG (…and others) on one machine opens the potential for growth in product offerings. While the inclusive dryerless technology improves energy efficiency by eliminating offline crystallizing and drying, which furthermore, allows process scrap to be immediately reintroduced into the extrusion process. Having one piece of machinery that allows you to expand your market potential, save on energy and resource costs, and maximize output by eliminating the drying process, is worth considering.

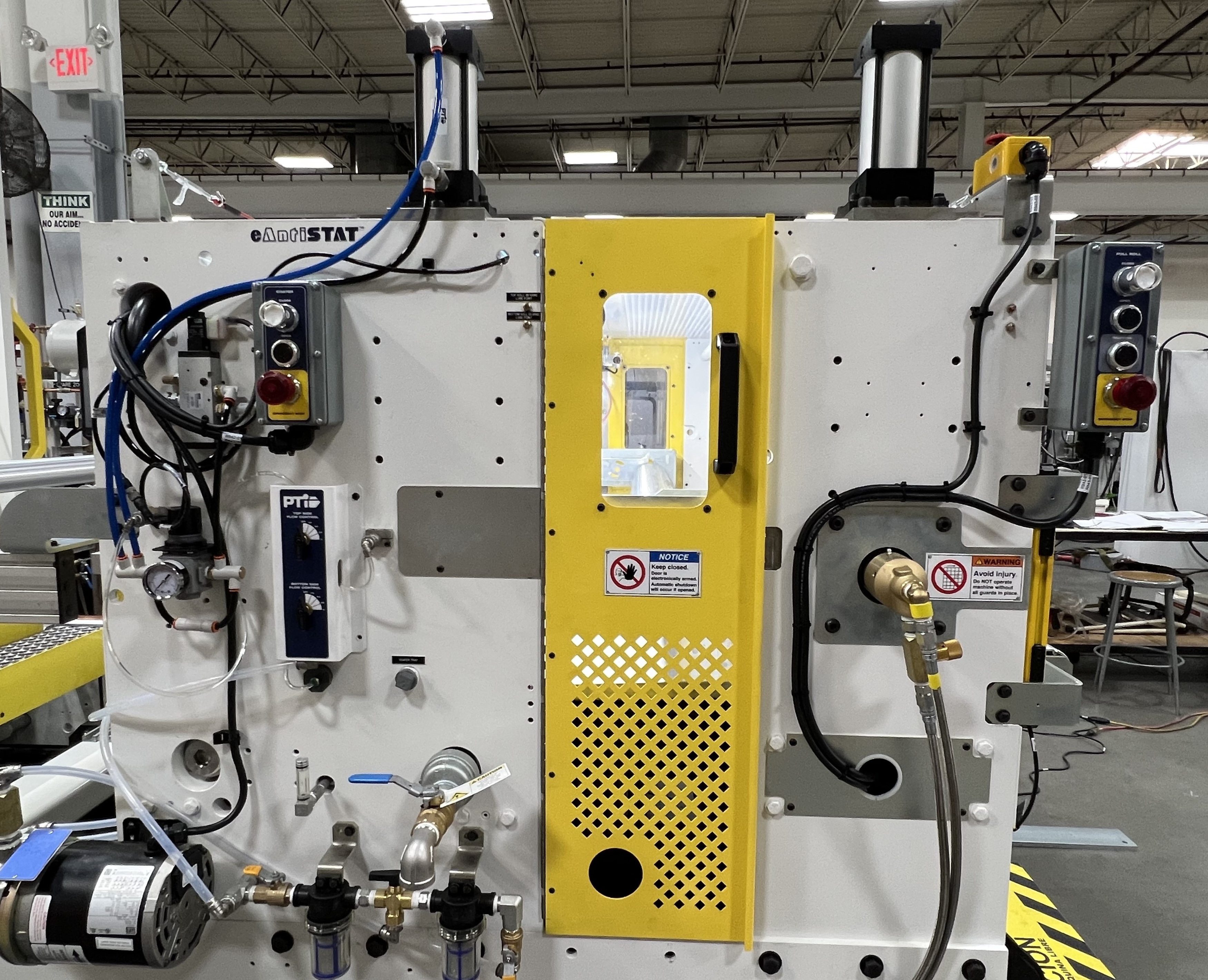

Listed below are specifications for this month's featured system. The configuration can be used as an inline system for PET, PP, PS, HDPE, filled and unfilled materials, or it can also be an offline system with the addition of a winder. This system is uniquely offered as part of the GENESIS™ Program, and has a 4 month lead time, as most of these components and sub-assemblies are in-stock at our factory in Aurora!

|

System Configuration:

|

|

|

|